Turbocharged cars are more popular than ever. Most of this is due to stricter emissions which can be extremely difficult to meet with a large naturally aspirated engine. One of the excellent benefits of having a turbocharged engine is the massive world of tuning that it opens up. Amongst enthusiasts who are looking to tune their turbocharged engine, there is enormous confusion about what a BOV is and how it’s different than a BPV. In this short article, we’re going to explain how each one works and how they’re different from each other.

What is the Purpose of a BOV or BCV?

Turbocharged engines work by using exhaust gasses exiting the engine to spin the turbo wheel which then creates positive pressure in the intake. This positive pressure from the turbocharger forces more air into the engine, and when combined with more fuel it increases horsepower. This is fine assuming that the throttle body is open and boosts can easily enter the engine. If the throttle body closes when the turbocharger is creating a boost, the pressure in the turbo piping and intercooler will spike dramatically. This pressure can force intercooler piping to blow off due to sheer pressure. The big issue with this pressure spike is the chance of it violently stopping the turbocharging from spinning or even spinning backward.

The purpose of a BOV/BCV is the allow that excess pressure to escape. It works through a vacuum port on the BOV/BCV which enables it to measure relative manifold pressure. When the throttle body closes, a vacuum inside the manifold will be created. If the relative manifold pressure drops below atmospheric pressure, the valve opens and allows air through it.

The BOV/BCV can be mounted on the intercooler piping or on the intercooler itself. In the case of many production vehicles such as the Ford Fiesta ST, the BCV is mounted directly on the intake housing of the turbocharger.

How a BOV Works?

A typical blow-off valve (BOV) vents all the excess boost pressure outside the turbo and intake system, which is known as venting to the atmosphere. Venting all boost to the atmosphere makes that iconic “push” noise that the stereotypical tuner car makes. By venting all the excess pressure to the atmosphere, you can safely remove a massive amount of pressure extremely quickly which is great for extremely high boost vehicles.

The problem with this design is how it can poorly affect throttle response. If you quickly lift the accelerator pedal while in boost all the pressure will be gone, which means when you get back on the throttle you’ll be starting from 0psi. This constant need to rebuilt boost pressure can be very obnoxious when on a canyon road or autocross course where throttle modulation may be necessary.

Depending on how your car is setup, using a blow-off valve may cause your car to run rich momentarily between shifts. This issue can happen because the air that vented to the atmosphere was already metered by the car’s airflow meter. Most of the time, however, this issue can be solved with a quality tune.

This issue can be solved by using an adjustable BOV which allows for some of the excess pressure to be routed back into the intake, which will slightly improve throttle response, especially when going from gear to gear. This adjustable BOV from Kinugawa Turbo Systems is designed to be bolted onto the td04 and td05 series compressor housing easily and is adjustable to vent 100% to the atmosphere or you can change the spring setup according to the boost pressure.

How a BCV Works?A Bypass-Compressor-Valve (BCV) is different than a BOV because it doesn’t vent the excess pressure to the atmosphere. Instead, it recirculates all the unused boost back into the intake system before the turbocharger. The design helps keep pressure much more consistent which improves throttle response. Most bypass-valves recirculate the air back into the turbo or intake after the airflow meter which helps eliminate tuning issues.

Bypass-valves are typically used in production vehicles because of the increased throttle response. A bypass-valve can also be much quieter which is great for a production vehicle. In the case of cars like the Ford Fiesta ST, the factory BCV does make quite a bit of noise, especially when an aftermarket air filter is added to the equation.

The biggest drawback of the BCV design is its ability to hold up to high horsepower. Many high horsepower turbo cars leave the inlet to the turbocharger completely open which leaves no place for the air to circulate. Even with an intake, it becomes difficult to recirculate that much air without running into airflow issues. For this reason, many high horsepowers or high boost cars run a vent to atmosphere BOV. If you want to stick with a BCV on your high horsepower setup, there are high flow BCVs such as the one from ours listed below.

The Rise of BCV Spacers

With more production vehicles using turbocharged engines, BCV spacers have become extremely popular. A lot of manufacturers do everything they can to decrease any turbocharger sound, including making the OEM BCV system super quiet. If you want more of that “psh” noise when you let off the throttle but want to keep the stock BCV system, then a BCV spacer is the perfect solution. A spacer works by spacing the BCV away from where it’s bolted. On the spacer, there are cutouts that allow air out when the BCV opens. The spacer effectively takes a 100% recirculating BCV and makes it a 100% VTA BOV, by allowing all the air out the spacer before it can be routed back to the intake as it was designed.

In theory, this would lead to poorer throttle response and more turbo lag, but on many vehicles, the stock turbocharger is as small as it can be to meet the manufacturers' power goals. With a tiny turbocharger you have superb throttle response and almost no lag, and adding a BCV spacer is unlikely to make any noticeable difference. As we mentioned earlier, depending on how your car is setup, using a BCV spacer may cause your car to run rich momentarily between shifts.

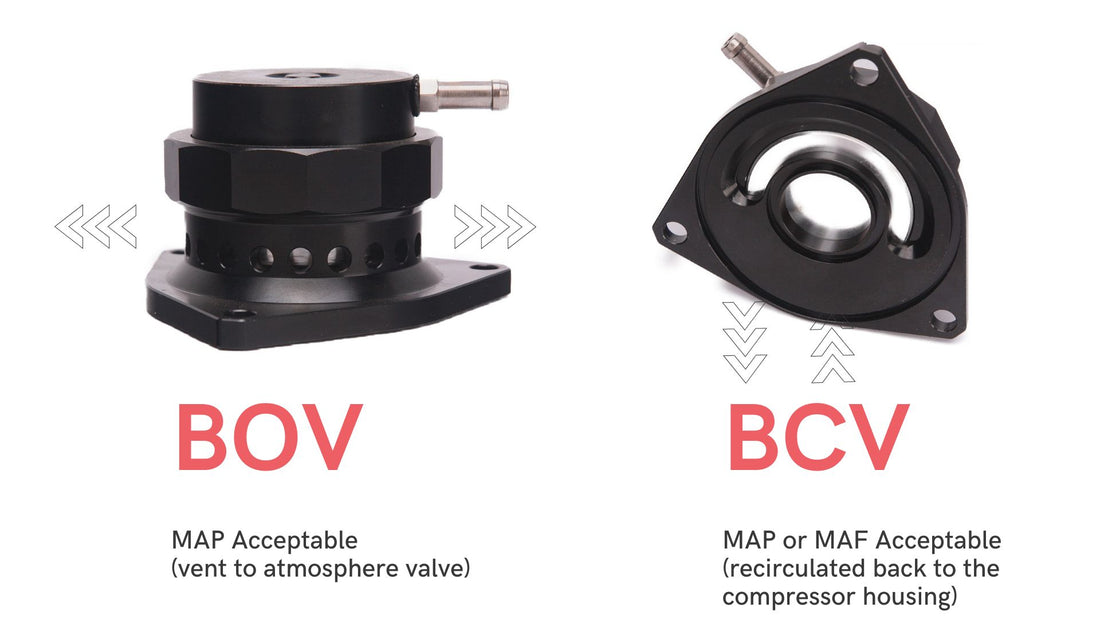

BOV or BCV: Using the proper blow off valve (BOV) or bypass compressor valve (BCV) affects the system performance. There are two main types to consider.

1. MAP (Manifold Absolute Pressure) sensor uses either a vent to atmosphere valve or a recirculation valve.

– Connect signal line to manifold source

– Surge can occur if spring rate is too stiff

2. MAF (Mass Air Flow) sensor uses a recirculation (bypass) valve for best drivability.

– Connect signal line to manifold source

– Position valve close to the turbo outlet for best performance (if valve can handle high temp).

– Surge can occur if valve and/or outlet plumbing are restrictive.

All of this information may be hard to digest. All you need to remember is that a BOV vents all the excess pressure to the atmosphere, an adjustable BOV vents some of the excess pressure to the atmosphere, and some of it back into the intake system, and a BCV vents all the excess pressure back into the intake before the turbocharger. If you have any questions regarding which BOV/BCV is right for your car, please do not hesitate to contact us. email: support@kinugawaturbosystems.com

1 comment

Hello. I’m owner of a Volvo 850 turbo 1994 with a 15G turbo, and a Forge BOV, having constant MAf codes.

Looking for a upgrade to 19t turbo a BOV or spacer.

Questions:

Could I fit a 19 t without modifications on flanges?

Which is the best recirculation valve or blow valve for my car, I want to have a little FUSSSHHHHH, but no code..

Kind regards

Rodolfo