Technologies

Our Missions

Just less than 3 steps! Easily Customize DROP-IN or BOLT-ON turbocharged solutions helping enthusiasts to Boost Creativities and Transcend Boundaries.

Step1. Choose Your Application

Step 2. Choose Target Horsepower Range

Step 3. Spool Time Fine-Tune

Design by Ken Wu (CEO)

Our Technologies

- The CFD Analysis and 360-Degree Performance Thrust Design.

|

|

| The CFD design of the turbine wheel meets the exhaust, thus increasing gas flow, reducing back pressure, and lowering temperatures, allowing a safer, higher boost level. This process also gives the advantage of removing one material, lightening the turbine wheel, thus reducing rotational mass and improving the moment of inertia. |

The 360 degree design performance thrust bearing kit, It's durable at heavy loads without loss in transient response. |

- Compressor Wheel Design

The free surface point milling process will be applied on our KX type wheel. It can build more air pressure and increase much better flow efficiency.

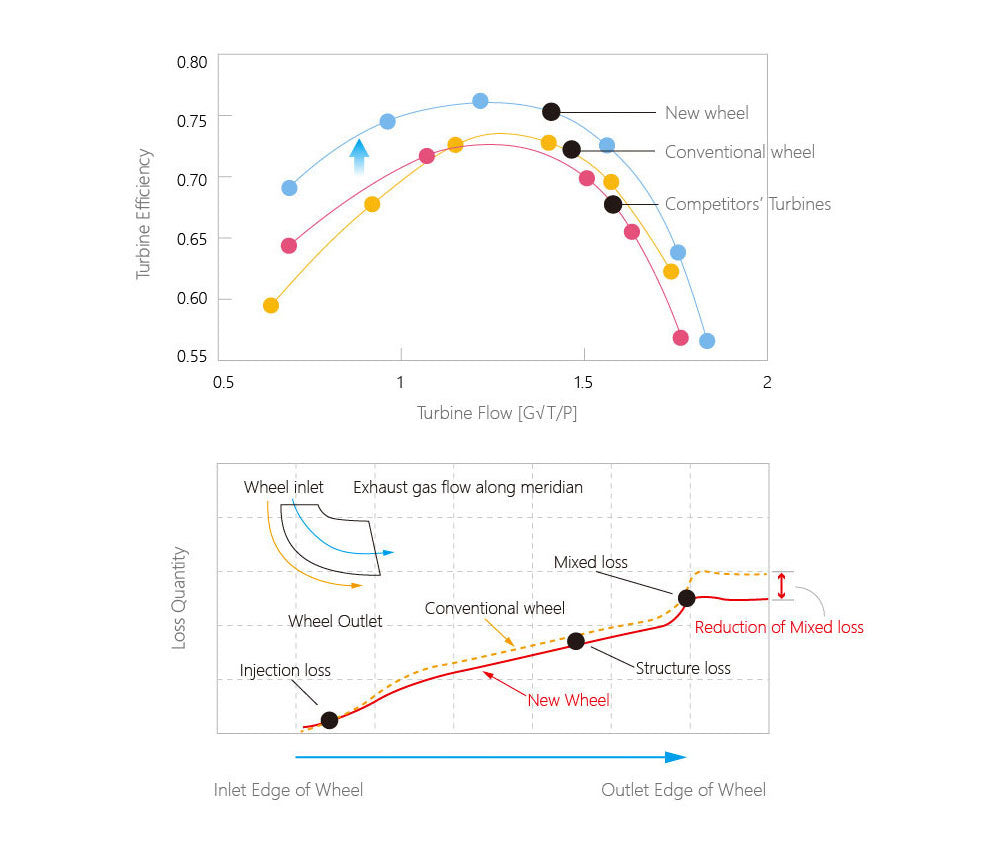

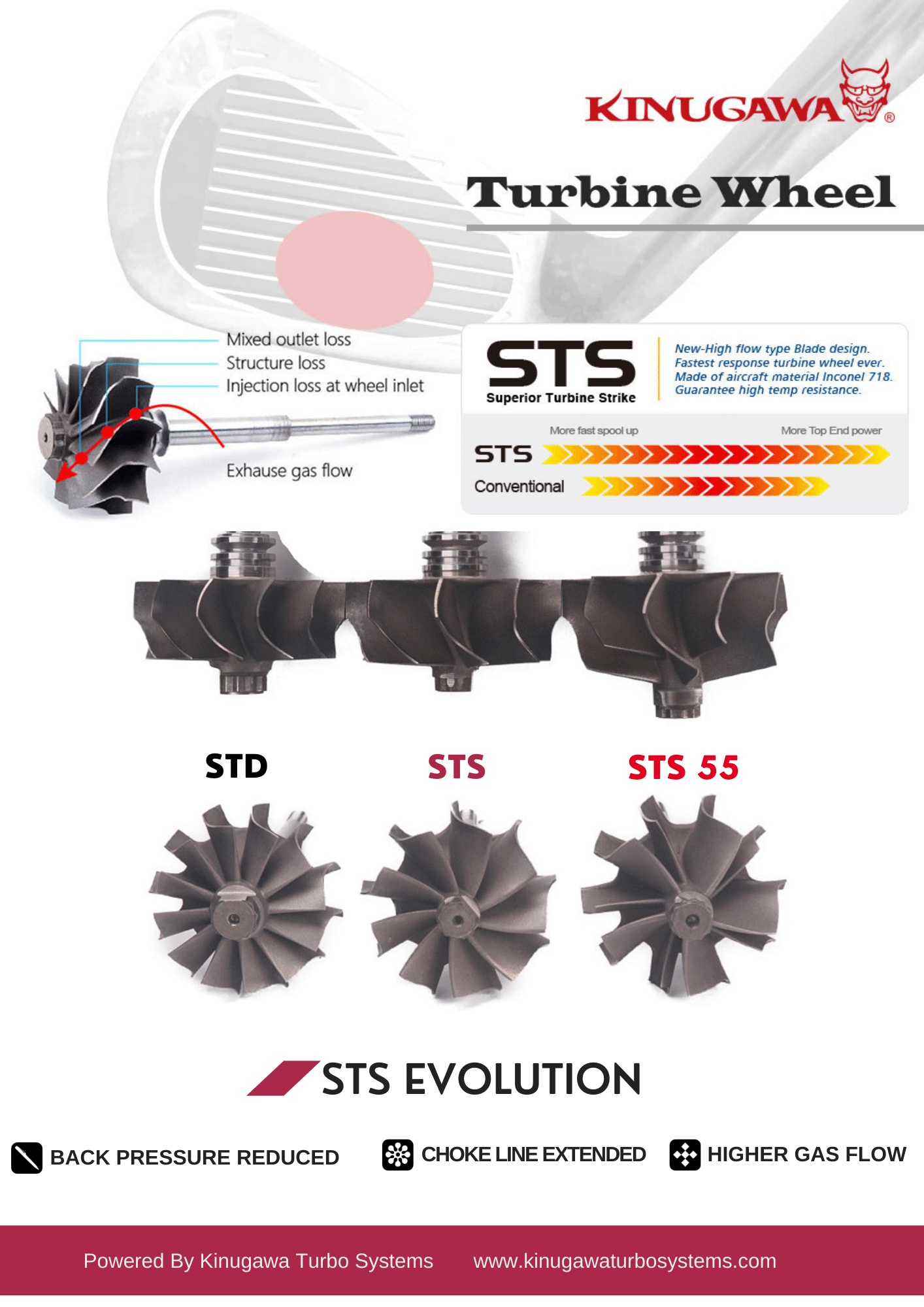

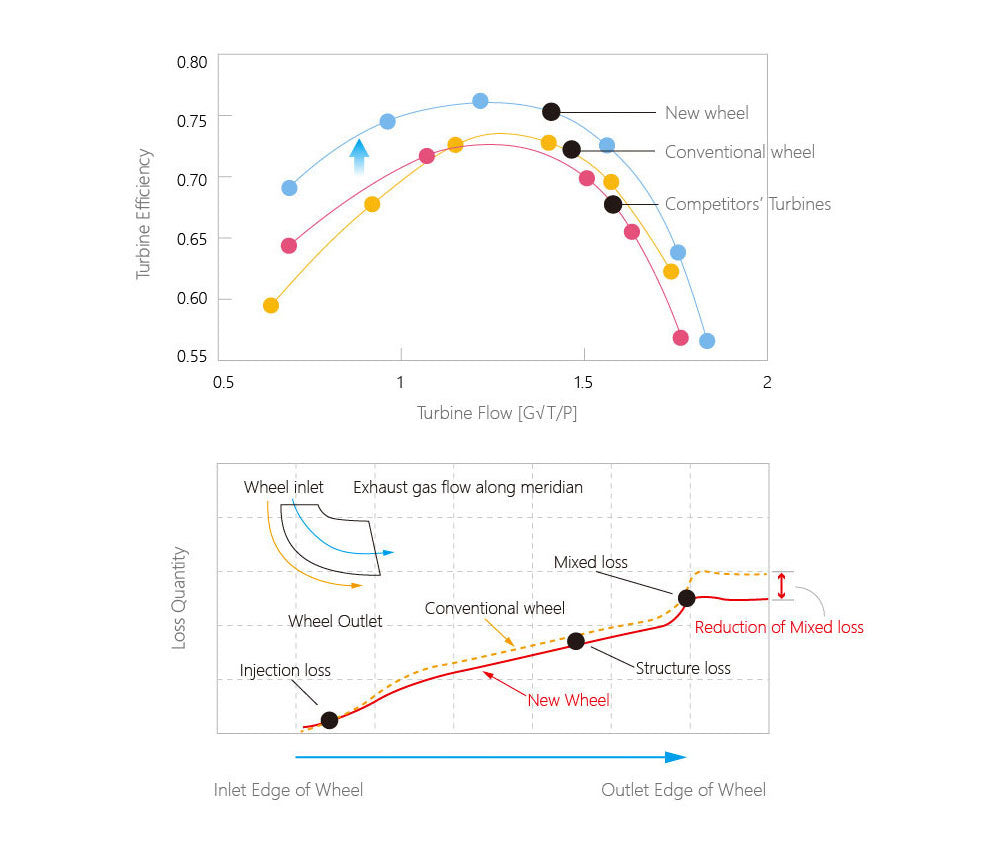

- Turbine Wheel Design

The STS (Superior Turbine Strike) turbine wheel will take a shorter time (a 5-8% decrease) to build boost, achieve higher top-end speeds, and extend the choking area. This is because it has less inertia and restriction compared to an 11 or 12-blade STD turbine, and it also has more flow capacity. The STS 55 turbine wheel improve from STS, inspired by cutting-edge turbine aero, employs a patent-pending splitter-blade design to achieve unprecedented levels of flow capacity and efficiency. This translates to a significant reduction in exhaust manifold pressure (EMAP) by operating at a reduced expansion ratio, unlocking a multitude of performance benefits:

-

Unleashed Engine Power: Reduced backpressure, a direct result of the lower expansion ratio, allows your engine to breathe freely, resulting in a substantial boost in horsepower and torque.

-

Enhanced Volumetric Efficiency: Lower EMAP, achieved through optimized expansion, improves the engine's ability to ingest air and fuel, contributing to heightened responsiveness and overall efficiency.

-

Reduced Knock Sensitivity: Lower EMAP mitigates the risk of detonation, permitting more aggressive tuning and further power extraction.

-

Cooler Engine Operation: The optimized expansion ratio contributes to lower exhaust gas temperatures, alleviating thermal stress on your engine and enhancing reliability.

The STS 55's innovative splitter-blade design transcends the traditional trade-off between flow capacity and efficiency. By refining blade loading and minimizing blockage in the throat area, it achieves the high flow of a low blade-count turbine while maintaining the efficiency of a high blade-count configuration.

The STS Advanced (Ceramic Dual Ball Bearing 9 Blades) enhances the STS (Journal Bearing 9 Blades) that improves the response speed (time needed to build boost) 10-15% as well as being more durable due to the improved shaft dynamics control. The increased power comes from the enhanced design. It utilizes an inner and outer race with rollers or balls between the two races. The inner race is pressed onto the turbo shaft, and the outer race is pressed into the CHRA. The rollers or balls replace the oil’s “job” of controlling the turbo shaft’s orientation but do still need to be lubricated.

Balance Process

Precisely balancing our turbochargers is a key critical factor for longevity and performance. Good balance improves acoustics also. Subsequent great care is taken with all Kinugawa brand turbochargers in this regard. Firstly parts are balanced at slow speeds up to 2,800 RPM in multiple planes using our single parts machine, then components are assembled, and then the CHRAs have dynamically balanced yet again but this time at up to 100,000 RPM in multiple planes using our in house VSR machine to acquire the ultimate equilibrium, to a standard far higher than OEM. We supplied a balance test result document.

We launched the anti-counterfeit tag that comes with the Kinugawa turbocharger and CHRA balance report. Customers can check authentic status, product information, instruction of installation, troubleshooting via our cloud system.